About the chemical industry

The chemicals sector can be divided into three main categories.

The first is the "tooling business" such as automobile design / inspection jigs and mold materials / molding. High-performance Teradite® epoxy resin, synthetic wood for design tools, various special boards, adhesives, systems and new alloys (AL). We provide new materials such as -ZAS).

The second is the "contract production business" of our customers' products. At our Tsukuba factory, we stir, disperse and synthesize products according to customer's request.

The third is the "chemical business," which mainly provides special chemical products for the construction and civil engineering industries. Recently, we have focused on handling overseas chemicals and have received high praise from QCD.

The first is the "tooling business" such as automobile design / inspection jigs and mold materials / molding. High-performance Teradite® epoxy resin, synthetic wood for design tools, various special boards, adhesives, systems and new alloys (AL). We provide new materials such as -ZAS).

The second is the "contract production business" of our customers' products. At our Tsukuba factory, we stir, disperse and synthesize products according to customer's request.

The third is the "chemical business," which mainly provides special chemical products for the construction and civil engineering industries. Recently, we have focused on handling overseas chemicals and have received high praise from QCD.

High-performance epoxy resin compound "TERADITE®"

We have a wide variety of epoxy-based compounds that are the basis of manufacturing, from workable resins for design studies and inspection tools, tooling fields for gel coating and lamination to molding systems (Teradite® resin type).

In addition, the resin mold release agent MO-7 (an evolved version of the former MO-3), which has been patronized by various parties, has been recognized for its applicability and releasability, and has been released from the market as one of our long-selling products. We have received solid support.

Such long-standing resin manufacturing know-how is utilized not only in the tooling field but also in the resin mold field, and in recent years it is possible to introduce resins for infusion that can be used for carbon composite molding, which is a future technology.

In addition, the resin mold release agent MO-7 (an evolved version of the former MO-3), which has been patronized by various parties, has been recognized for its applicability and releasability, and has been released from the market as one of our long-selling products. We have received solid support.

Such long-standing resin manufacturing know-how is utilized not only in the tooling field but also in the resin mold field, and in recent years it is possible to introduce resins for infusion that can be used for carbon composite molding, which is a future technology.

Touring business

For design master model | TRW-050 TRW-1065A |

For injection and high heat resistance | M-507 modified |

For high-precision casting Gel coat | MH-3 |

For mold backing | TLR-2 TCR-18 (heat resistant type) |

Products handled

In the touring business, we handle products that are useful from the perspective of "manufacturing." For example, we provide adhesives and design materials from various manufacturers, not limited to our own product "Teradite®". We are sure that you will be satisfied with our proposals in a wide variety of product lineups, from rigid urethane blocks that are indispensable to the molding industry to building materials such as styrofoam and waterproofing agents.

Urethane board lamp (Germany) for design master model | SB-0080, SB-0470, etc. |

For inspection jig | MB-0720, WB-1700, etc. |

Foamed urethane styrol | KM series W series, etc. |

Instant Adhesive High Pressure Gas Chemistry / Alpha Giken | Pegalock, spray primer, etc. |

Various mold release materials | Full Omart P series, etc. |

Silicon resin (Shin-Etsu Chemical) | Molding silicon, etc. |

Thermosetting resin | Terradite® for infusion |

Molding system (Lamp) | Various epoxy resins, urethane resins, etc. |

Various machines / agitators | VS750 |

Contract production business

Features

- Compounding of high-viscosity liquid resin (especially thermosetting resin), dispersion of various fillers, and fine filling

- Various planetary mixers (5L, 30L, 200L, 400L, 700L) can be used for laboratory-level, small to large lot production.

- Various inspection equipment, quality control

Chemicals Business (Rhodes Shokai)

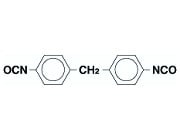

- Urethane resin and epoxy resin raw materials

- Various resin additives (plasticizers, light stabilizers, flame retardants, etc.)

- Handling of various imported raw materials

- Contract production